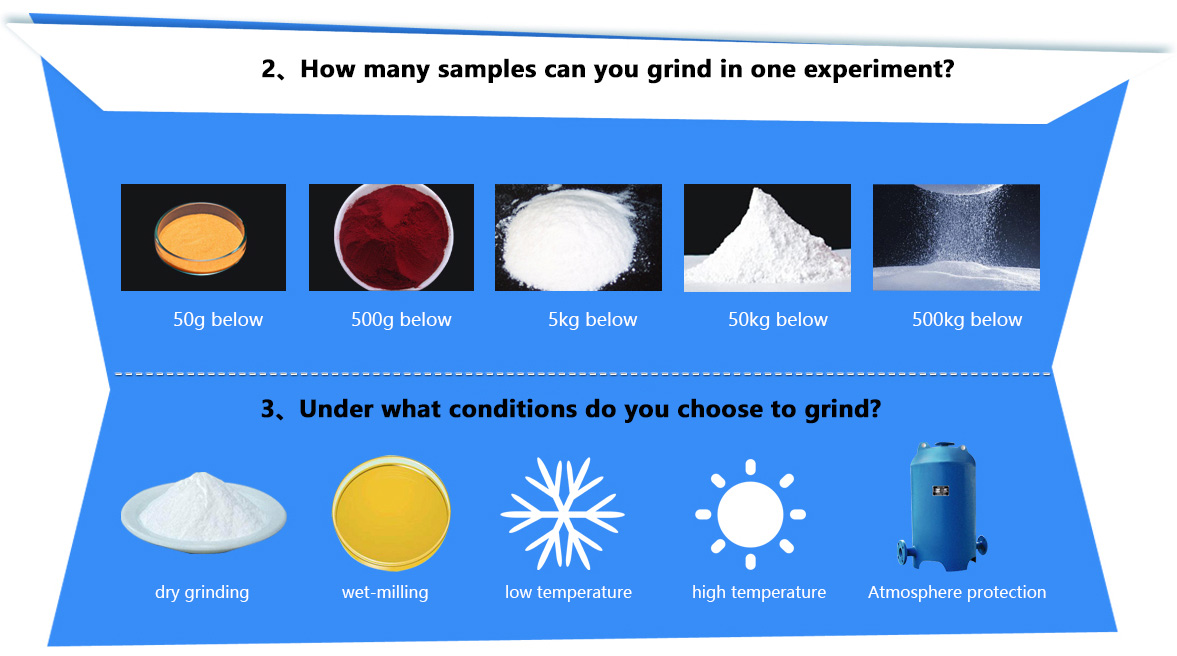

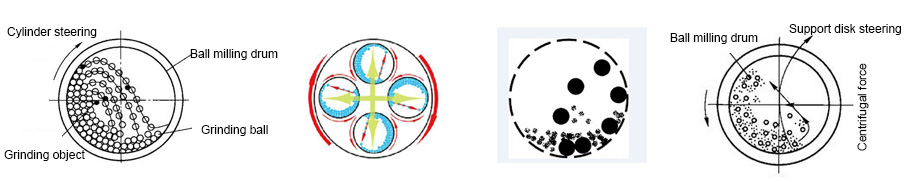

The laboratory ball mill has a relatively small processing capacity and is generally used for experimental research or small-scale sample production (volume 0.5-500L, processing capacity 100g-500kg). The laboratory ball mill is a general term, which can be divided into different types according to different structures, such as planetary ball mills, stirred ball mills, drum ball mills, and vibrating ball mills, each with different grinding principles. Based on grinding conditions, it can be divided into dry grinding, wet grinding, or dual-purpose laboratory ball mills.

Grinding and Crushing Principle of Laboratory Ball Mill:During operation, the laboratory ball mill uses the combined forces of shearing, friction, impact, collision, and compression of the grinding balls to crush and grind the material.

Schematic Diagram of Ball Mill Grinding and Crushing Principle

According to different power principles, small laboratory ball mills are mainly divided into the following categories: planetary ball mills, drum ball mills, stirred ball mills, and vibrating ball mills. In addition, there are other types such as fast ball mills, conical ball mills, and laboratory crushers.